Manufacturers usually build metal workbenches using stainless steel because of its strength and anti-corrosive properties. The stainless steel creates a rigid frame and gives the workbench a finished look. Steel workbenches are also very easy to clean if the bench is being used in a setting where cleanliness is important. Read More…

Our workbenches come in a variety of styles including ergonomic height adjustable, chemical resistant, ball transfer surface, computer stations, laminar flow stations and more.

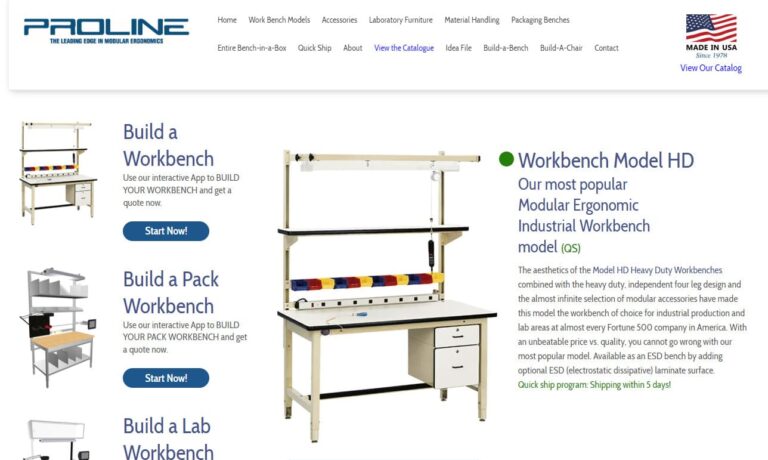

As a workstation manufacturer, Pro-Line offers industrial furnishing that increases employee productivity through creating an improved employee work environment.

This progressive workstation manufacturer creates flexible, ergonomic solutions for a variety of work environments. ESD, clean room & lab benches, ball transfer assembly workstations, material handling flow rack stations, quick ship modular work benches & great accessories. With everything in-house, we ensure quality workmanship, great lead times & competitive prices for even custom bench designs.

Production Automation Corporation has been a distributor of products for general industrial manufacturing since 1973. We specialize in providing items used in electronic assembly and medical device manufacturing. As a manufacturer's representative, we have a large line of products such as anti fatigue mats, safety wear, chairs, cleaners, hand tools, microscopes, cabinets, workbenches and more.

Worksmart Systems designs ergonomic workstations providing customers with the necessary tools to reach six sigma lean manufacturing goals by eliminating waste, preventing defects and improving line efficiency. These are accomplished by our Fleximate® workstations such that our products can be joined together to create optimized assembly cells. We also offer floor and table top stations.

More Metal Workbench Manufacturers

Metal Workbenches: The Ultimate Guide to Industrial Workstation Solutions

Looking for a durable, versatile, and long-lasting metal workbench? Whether you're outfitting an industrial workshop, a commercial manufacturing facility, or a home garage, choosing the right metal workbench is essential for safety, productivity, and organization. In this comprehensive guide, we’ll explore the different types of metal workbenches, their applications, key features, and expert tips for selecting the best workbench for your needs.

What Is a Metal Workbench? Understanding Industrial Workbenches

A metal workbench is a sturdy workstation constructed primarily from steel or aluminum, designed to withstand demanding tasks and heavy loads. These workbenches serve as the foundation for countless industries, providing a reliable surface for assembly, repair, fabrication, and storage. Their robust construction makes them ideal for environments where durability, safety, and efficiency are top priorities.

Common Uses for Metal Workbenches

- Metal fabrication and welding shops

- Automotive repair and maintenance facilities

- Carpentry and woodworking

- Electronics assembly and testing labs

- Home garages and hobby workshops

- Packaging and shipping departments

- Assembly lines and production plants

Types of Metal Workbenches: Find the Perfect Fit for Your Workspace

Metal workbenches come in a wide range of designs to suit varying requirements. Here are the most popular types:

- Standard Metal Workbenches: Simple, flat work surfaces constructed from sheet metal and steel frames. Ideal for general assembly or repair tasks.

- Heavy-Duty Industrial Workbenches: Built to handle extremely heavy loads, often featuring reinforced steel frames and thick work surfaces. Perfect for manufacturing plants and fabrication shops.

- Stainless Steel Workbenches: Corrosion-resistant and hygienic, making them perfect for food processing, laboratories, and clean rooms.

- Mobile Metal Workbenches: Fitted with heavy-duty casters or wheels for easy movement and repositioning within large workspaces.

- Adjustable Height Workbenches: Allow workers to modify the bench height for ergonomic comfort, enhancing productivity and safety.

- Folding Metal Workbenches: Feature collapsible legs for convenient storage and portability—ideal for compact spaces and mobile operations.

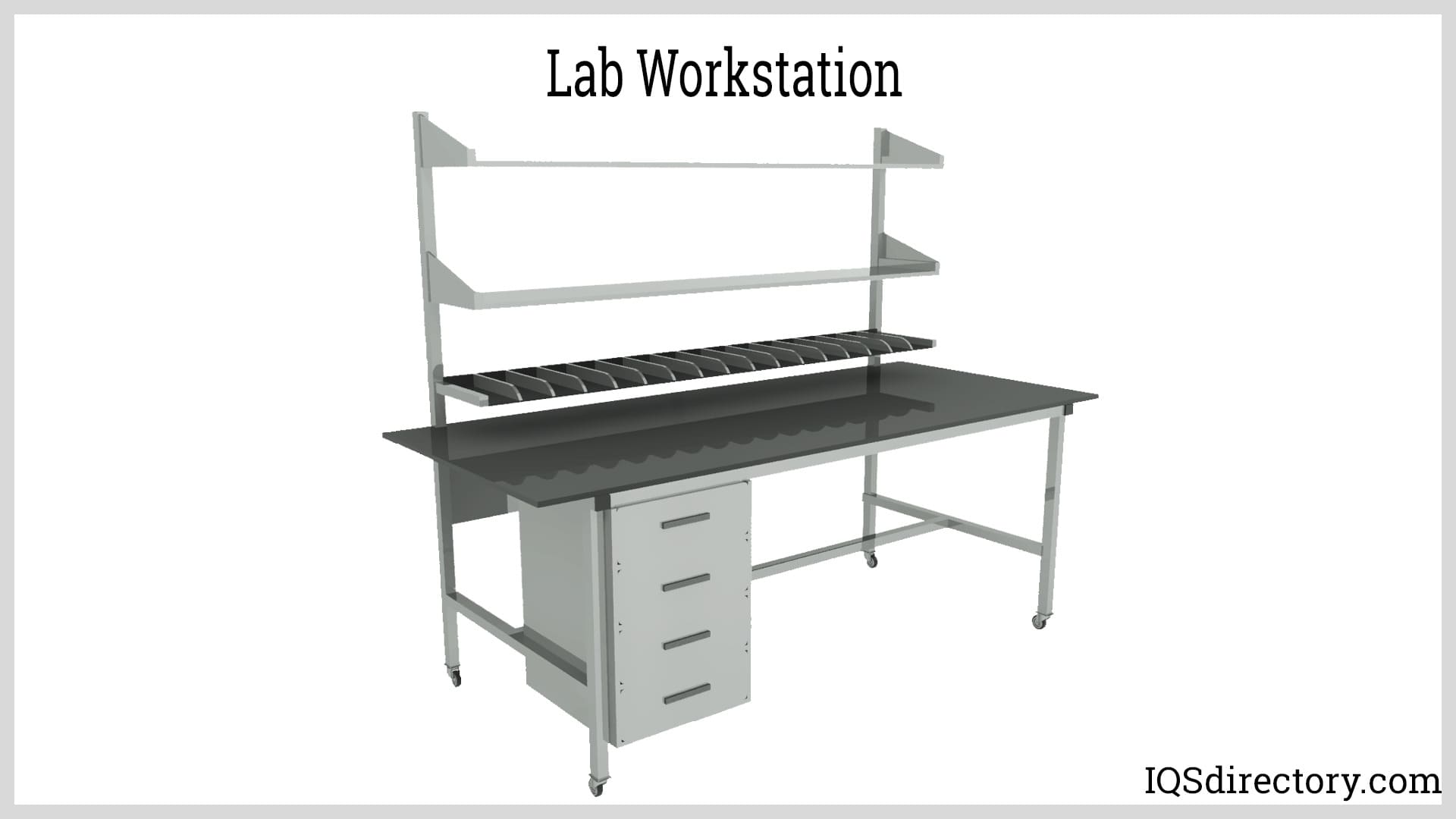

- Workbench with Storage: Integrated drawers, cabinets, and shelves for organized tool and equipment storage.

- ESD-Safe Workbenches: Designed for electronics assembly, these benches prevent static discharge to protect sensitive components.

Which Type of Metal Workbench Is Right for Your Industry?

Not sure which workbench will suit your facility? Contact our experts for personalized recommendations based on your industry, workflow, and space requirements.

Key Features and Accessories: Customizing Your Metal Workbench

When comparing metal workbenches for sale, consider which features and accessories will enhance your work processes. Modern industrial workbenches offer a wide array of customization options:

- Integrated shelving for tool and parts organization

- Cabinet doors and lockable drawers to secure valuable equipment

- Overhead lighting for improved visibility

- Built-in power strips and electrical outlets for powering tools and electronics

- Pegboards or tool rails for convenient tool access

- Stainless steel or powder-coated surfaces for corrosion resistance and easy cleaning

- Adjustable feet or casters for leveling and mobility

- Vice mounts and fixture holes for specialized tasks

How to Choose the Right Accessories?

Think about your daily tasks. Do you need quick access to tools? Will you be using heavy equipment that requires electrical outlets? Is portability important in your workspace? Asking these questions will help you select the most beneficial features for your metal workbench.

Manufacturing Process: How Are Metal Workbenches Made?

Understanding the manufacturing process helps you evaluate the quality and durability of a metal workbench. Here’s a breakdown of typical production steps:

- Material Selection: Industrial-grade steel, aluminum, or stainless steel sheets are chosen based on the bench’s intended application and required load capacity.

- Cutting and Shaping: Metal sheets are precision-cut and shaped into components such as legs, frames, and work surfaces using CNC machines, laser cutters, or plasma cutters.

- Welding and Assembly: Components are either hand-welded by skilled fabricators or assembled using automated welding machines. Automated welders ensure strong, uniform joints—critical for structural integrity, especially if the workbench will support heavy machinery or equipment.

- Finishing: Surfaces are treated with powder coating, paint, or polishing for enhanced durability and corrosion resistance.

- Accessory Integration: Shelving, drawers, electrical outlets, lighting, and other accessories are installed as per the customer’s specifications.

- Quality Inspection: Final workbenches undergo rigorous testing to ensure they meet load-bearing, safety, and finish standards.

Why Is Quality Welding Important for Industrial Workbenches?

High-quality welding ensures the stability and longevity of your metal workbench. Inferior welds can lead to structural failure under heavy loads, posing safety risks and costly downtime. When shopping for industrial workbenches, always inquire about the welding techniques and quality standards used by the manufacturer.

Benefits of a Metal Workbench: Why Choose Metal Over Wood or Plastic?

Metal workbenches offer a wide range of advantages over their wood or composite counterparts, making them the preferred choice for commercial, industrial, and high-demand home workshops.

- Strength and Stability: Engineered to support heavy machinery, parts, and tools without flexing or warping.

- Durability: Resistant to wear, impact, moisture, and chemicals—ideal for harsh industrial environments.

- Longevity: A well-built metal workbench can last for decades with minimal maintenance.

- Customizability: Easily fitted with accessories such as shelves, cabinets, and lighting to adapt to specific workflows.

- Cleanliness: Metal surfaces are easy to sanitize, crucial for laboratories and food-related industries.

- Fire Resistance: Unlike wood, metal does not burn, providing an added layer of safety in hazardous environments.

- Security: Integrated locks and secure storage options keep valuable tools and equipment safe.

- Professional Appearance: A sleek, industrial aesthetic enhances the look and feel of any workspace.

Want to Compare Metal and Wooden Workbenches?

Curious about the differences in strength, lifespan, and maintenance requirements? Read our in-depth comparison of metal vs. wood workbenches to see which is right for your application.

Applications of Metal Workbenches: Industry-Specific Solutions

Because of their versatility, metal workbenches are integral in a wide variety of industries. Here are some common use cases:

- Automotive Workshops: Support engines, transmissions, and heavy auto parts during repairs and rebuilds.

- Welding and Fabrication Shops: Provide a spark-resistant, sturdy platform for cutting, grinding, and welding operations.

- Laboratories & Cleanrooms: Stainless steel workbenches resist corrosion and are easy to sterilize, supporting sensitive experiments.

- Manufacturing Assembly Lines: Facilitate efficient part assembly, quality control, and packaging workflows.

- Maintenance Facilities: Store tools, organize parts, and provide a safe surface for equipment repair.

- Commercial Kitchens: Stainless steel benches meet health codes and withstand intense daily cleaning.

- Home Garages & DIY Shops: Support everything from woodworking to electronics repair and hobby projects.

What Size Workbench Do You Need?

Dimensions matter! Measure your workspace and consider the largest item you'll place on the bench. Standard sizes typically range from 48 to 96 inches long, but custom sizes are available for unique needs. Ask us about custom metal workbench sizing to ensure a perfect fit for your shop or garage.

How to Choose the Best Metal Workbench: Buying Guide & Decision Factors

With so many options on the market, selecting the right metal workbench can feel overwhelming. Here are the top factors to consider when evaluating different models:

- Load Capacity: Consider the maximum weight the bench will need to support. Heavy-duty industrial workbenches often handle 2,000 lbs or more.

- Work Surface Material: Choose between steel, stainless steel, or powder-coated metal surfaces based on application and environment.

- Dimensions: Ensure the workbench fits your available space without crowding your workflow.

- Mobility: Do you need wheels or casters for easy movement, or a stationary bench for maximum stability?

- Storage Options: Integrated drawers, shelves, and cabinets help keep tools and supplies organized.

- Ergonomic Design: Adjustable height workbenches reduce strain and improve comfort for users of different heights.

- Electrical Integration: Built-in outlets and lighting can streamline operations and increase safety.

- Budget: Factor in your price range, but consider that a high-quality metal workbench is a long-term investment.

- Brand and Warranty: Reputable manufacturers offer warranties and customer support to protect your purchase.

Compare Top Metal Workbench Brands

Wondering which manufacturer offers the best value for your industry? Explore our review of leading metal workbench brands and see how they stack up in terms of quality, features, and price.

Custom Metal Workbenches: Tailored Solutions for Unique Needs

Off-the-shelf metal workbenches may not always meet the specific requirements of your business. Many manufacturers offer custom metal workbench design services, allowing you to specify dimensions, materials, finishes, and accessory integration. Customization ensures your workstation supports your workflow, maximizes productivity, and meets all safety standards.

When Should You Consider a Custom Workbench?

- You have unique space constraints or require non-standard dimensions

- Your workflow demands specialized features or accessory integration (e.g., specific tool mounts, ESD-protection, or chemical resistance)

- You need brand-specific colors or logos for a cohesive facility appearance

- Compliance with industry-specific regulations (e.g., FDA, ISO, or OSHA standards)

Ready to design your ideal workstation? Request a custom metal workbench quote today and collaborate with our engineering team to build your perfect solution.

Maintenance and Care: Keeping Your Metal Workbench in Top Condition

Proper maintenance prolongs the lifespan of your metal workbench and ensures workplace safety. Here are essential tips for care and upkeep:

- Regular Cleaning: Wipe down work surfaces after use to prevent buildup of grease, chemicals, or debris

- Inspect Joints and Welds: Periodically check for signs of stress or damage, especially if supporting heavy loads

- Tighten Fasteners: Ensure all bolts, screws, and hardware remain secure over time

- Lubricate Moving Parts: Apply lubricant to casters, drawer slides, and hinges to maintain smooth operation

- Touch Up Coatings: Repair scratches or chips in powder-coated or painted surfaces to prevent rust

- Replace Worn Accessories: Swap out damaged drawers, shelving, or electrical components as needed

How Long Do Metal Workbenches Last?

With regular maintenance, a high-quality industrial metal workbench can last 20 years or more—outperforming most wooden or composite alternatives. Investing in proper care not only extends lifespan but also preserves resale value and workplace safety.

Frequently Asked Questions About Metal Workbenches

- What is the best workbench for heavy-duty use? Heavy-duty industrial steel workbenches are ideal for supporting large machinery, engines, and heavy tools. Look for reinforced frames and thick steel tops.

- Can I use a metal workbench outdoors? Many metal workbenches feature weather-resistant coatings, making them suitable for covered outdoor applications. Stainless steel options offer maximum corrosion resistance.

- Are metal workbenches safe for electrical work? Yes, but choose models with ESD protection and integrated outlets designed for electronics assembly or repair work.

- How much weight can a metal workbench support? Load capacities range from a few hundred to several thousand pounds. Always confirm manufacturer specs for your intended application.

- Can I add wheels or casters to my workbench? Many models offer mobility kits or pre-installed casters for easy movement—perfect for changing layouts or multipurpose workspaces.

Start Your Search for the Perfect Metal Workbench

Ready to upgrade your workspace with a high-performance metal workbench? Whether you need a standard steel workbench, a mobile workstation, or a fully customized industrial solution, our team can help. Browse our selection of metal workbenches for sale, or contact us for expert advice and personalized recommendations.

Still Have Questions?

Explore our extensive FAQ section, or reach out directly to discuss your project requirements. Discover why metal workbenches are the gold standard for industrial, commercial, and home workshops worldwide!

55 Gallon Drums

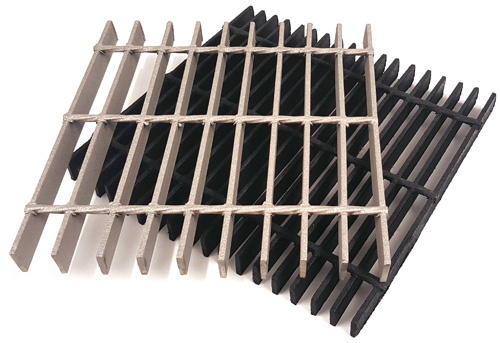

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services