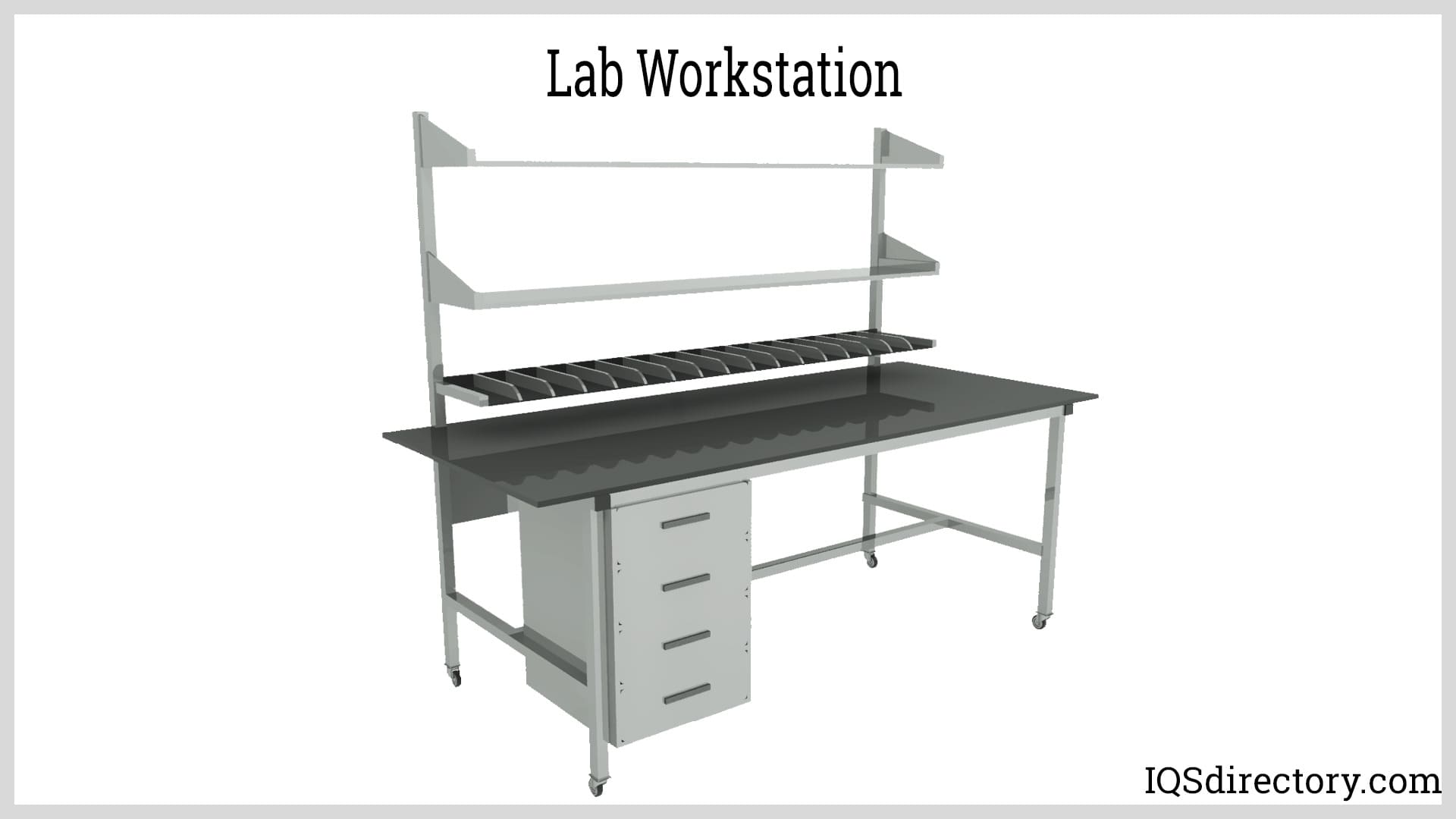

A laboratory workbench is a workstation that offers a surface and space to carry out tests, store laboratory equipment, and allow work for technicians and students in a science lab. They are mostly found in chemical and biological sciences. Laboratory workbench tabletops are commonly made from inert materials since fuel and water sources are nearby or built into the bench. Read More…

Our workbenches come in a variety of styles including ergonomic height adjustable, chemical resistant, ball transfer surface, computer stations, laminar flow stations and more.

As a workstation manufacturer, Pro-Line offers industrial furnishing that increases employee productivity through creating an improved employee work environment.

This progressive workstation manufacturer creates flexible, ergonomic solutions for a variety of work environments. ESD, clean room & lab benches, ball transfer assembly workstations, material handling flow rack stations, quick ship modular work benches & great accessories. With everything in-house, we ensure quality workmanship, great lead times & competitive prices for even custom bench designs.

Production Automation Corporation has been a distributor of products for general industrial manufacturing since 1973. We specialize in providing items used in electronic assembly and medical device manufacturing. As a manufacturer's representative, we have a large line of products such as anti fatigue mats, safety wear, chairs, cleaners, hand tools, microscopes, cabinets, workbenches and more.

Worksmart Systems designs ergonomic workstations providing customers with the necessary tools to reach six sigma lean manufacturing goals by eliminating waste, preventing defects and improving line efficiency. These are accomplished by our Fleximate® workstations such that our products can be joined together to create optimized assembly cells. We also offer floor and table top stations.

More Laboratory Workbench Manufacturers

Laboratory workbench table tops are a foundational component of any laboratory environment, providing the essential work surface for research, experimentation, and technical applications. Selecting the right laboratory workbench material is critical for ensuring safety, durability, and efficiency in daily laboratory operations. Workbench surfaces are available in a variety of high-performance materials, including self-edged laminate, edge-grained maple, composite resin wood, PVC-edged laminate, electrostatic dissipative (ESD) laminate, chemical-resistant laminate, epoxy resin, and stainless steel. Each laboratory countertop material offers unique properties suited for specific scientific, industrial, educational, and analytical environments.

Considerations for Choosing a Laboratory Workbench

When planning your laboratory layout or upgrading laboratory furniture, choosing the right lab workbench is a critical decision that influences workflow, safety, and compliance with regulatory standards. Laboratory workbenches are the backbone of scientific research and industrial testing facilities, serving as the primary platform for experiments, sample preparation, equipment placement, and data analysis. Understanding your laboratory’s specific needs and the available options for bench materials can significantly enhance productivity and longevity of the workspace.

- Durability: Laboratory workbench tops must be engineered to withstand the rigors of daily laboratory use. This includes resistance to physical impact, exposure to harsh chemicals, and long-term wear and tear. Look for materials that offer shock resistance, chemical resistance, and UV resistance to ensure a long service life.

- High-Quality Finish: A superior finish on a laboratory countertop not only enhances aesthetics but also improves functionality. The surface should be smooth, non-porous, and easy to clean, supporting stringent laboratory hygiene practices and compliance with laboratory safety protocols.

- Non-toxic and Hygienic: Workbench materials should be fully cured and non-toxic, minimizing the risk of contamination from microbes such as bacteria, germs, molds, and mildew. Selecting antimicrobial surfaces can support cleanroom environments and biosafety requirements.

- Chemical and Heat Resistance: Laboratory workbenches must be able to resist corrosive chemicals, solvents, acids, and bases commonly used in scientific applications. For labs handling volatile substances or conducting high-temperature processes, bench materials should also offer flame resistance and non-conductivity, ensuring safety and regulatory compliance.

- Meets Laboratory Application Requirements: Different laboratory disciplines require specialized features. For example, microbiology, analytical chemistry, electronics assembly, and pharmaceutical research may call for custom work surfaces such as ESD protection, sterile finishes, or moisture resistance. A contamination-free environment is essential for research integrity and product safety.

- Ergonomics and Adjustability: Ergonomic design improves user comfort and reduces the risk of workplace injuries. Adjustable laboratory workbenches, equipped with crank or electric height adjustment and ‘T’ or ‘C’ leg designs, enable users to tailor the workspace to specific tasks. Sufficient knee clearance (at least 19 inches or 48 cm deep) and optimal bench length (minimum 72 inches or 182 cm) are important for productivity. Heavy-duty benches with load capacities of at least 750 pounds (340 kg) are recommended for supporting laboratory equipment and instruments.

Types of Laboratory Workbenches

Laboratory workbenches come in a wide variety of configurations and materials, each designed to meet the demands of specific laboratory environments. Below are some of the most popular types of lab workbenches and their core characteristics, advantages, and recommended applications.

Epoxy Resin Lab Workbench

Epoxy resin workbench tops are a premier choice for laboratories that require robust, high-performance surfaces. Manufactured from a blend of resins, hardeners, and fillers, epoxy resin countertops are molded into a solid, non-porous slab that resists the absorption of liquids and chemicals. This makes them ideal for use in chemical, biological, and analytical laboratories where exposure to corrosive agents, solvents, or moisture is frequent.

Key benefits of epoxy resin laboratory workbenches include:

- Long-lasting durability and high structural integrity

- Attractive, sleek appearance suitable for both traditional and modern lab designs

- Superior resistance to chemicals, acids, bases, and organic solvents

- Non-porous surface prevents absorption of spills, enhancing hygiene and simplifying cleaning

- Excellent heat resistance, minimizing risk of cracking or blistering under normal laboratory conditions

- Moisture and water resistance, making them ideal for installation around sinks, fume hoods, and wet processing areas

- Low maintenance requirements, reducing long-term operational costs

Common use cases: Epoxy resin workbench tops are preferred in research labs, pharmaceutical laboratories, university science departments, and quality control environments that demand frequent exposure to chemicals and require a surface that is easy to decontaminate. Curious about how to maintain and clean epoxy resin laboratory surfaces? Learn more about epoxy resin countertop care.

Phenolic Resin Workbench Tops

Phenolic resin workbench tops offer a high-value alternative to epoxy resin, delivering approximately 90% of the same performance characteristics at a more cost-effective price point. Comprised of layers of kraft paper saturated with phenolic resin and thermally fused under high pressure, phenolic resin countertops are lightweight yet exceptionally durable.

Advantages of phenolic resin workbenches:

- Hard, non-porous surface resists moisture, chemicals, and bacteria

- Lightweight construction makes installation and reconfiguration easier

- Excellent resistance to fungal and microbial growth, supporting sterile environments

- Thermal stability up to 348.8°F (176°C)

- Highly customizable and available in a range of sizes and configurations

- Shorter lead times due to ease of manufacturing

Phenolic resin laboratory countertops are particularly suitable for educational science labs, medical research facilities, and food testing laboratories where contamination-free surfaces are essential. Their resilience to everyday wear makes them a smart investment for busy laboratory environments that prioritize both performance and budget.

Looking to compare epoxy resin vs. phenolic resin workbench tops? Click here for an in-depth comparison and selection guide.

Stainless Steel Laboratory Workbench

Stainless steel laboratory workbenches are renowned for their unparalleled durability, longevity, and hygienic properties. Fabricated from high-grade stainless steel alloys, these laboratory workstations maintain their structural integrity and appearance over many years of intensive use.

Benefits of stainless steel laboratory workbenches:

- Exceptional resistance to corrosion, stains, and rust—even in wet or corrosive environments

- Withstands heavy impact and continuous use without warping or cracking

- Thermal stability across a wide temperature range (up to 1400°F / 760°C)

- Non-porous, crevice-free surfaces simplify sanitation and support biosafety standards

- Minimal maintenance—easy to clean with standard disinfectants

- Ideal for sterile environments, such as clinical labs, pharmaceutical production, and food processing facilities

Stainless steel benches are also commonly used in environments with strict health and safety regulations, including cleanrooms, hospital laboratories, and electronics manufacturing. Considering stainless steel for your laboratory? Explore our comprehensive stainless steel workbench options and customization features.

Maple Wood Block

Maple wood block workbenches are highly valued for their classic appearance, natural strength, and versatile performance. Lab-grade maple is carefully selected for its smooth texture, light color, and minimal grain, making it a preferred choice in teaching labs, technical classrooms, and environments where aesthetics and resilience are both priorities.

Key features of maple wood laboratory workbenches:

- High Janka hardness score (1450 lbs), indicating superior strength and impact resistance

- Available in multiple grades and styles to suit various laboratory budgets and design preferences

- Cost-effective solution for labs that do not require extreme chemical or heat resistance

- Natural antibacterial properties and easy maintenance

- Can be refinished or sanded to extend service life

Maple wood block workbenches are ideal for dry labs, educational spaces, prototyping facilities, and labs where heavy mechanical work is performed. Interested in sustainable laboratory furniture options? Maple workbenches are an environmentally friendly choice due to their renewable sourcing and long lifespan.

ESD (Electrostatic Discharge) Workbench

Electrostatic discharge (ESD) workbenches are specifically engineered to protect sensitive electronic components and assemblies from damage caused by sudden electrical discharges. ESD-safe surfaces dissipate static electricity safely to ground, preventing malfunctions, data loss, or permanent damage to laboratory equipment and products.

Advantages of ESD laboratory workbenches:

- Integrated grounding systems for personnel, equipment, and surfaces

- Compliance with ANSI/ESD S20.20 and other global ESD standards

- Essential for electronics assembly, semiconductor testing, and microelectronics research

- Available in modular configurations for integration with fume hoods, laminar flow cabinets, and storage systems

Learn more about ESD workbenches and how to select the right ESD-safe table for your application.

Unsure if your lab requires ESD protection? Discover the signs and standards that indicate the need for ESD-safe laboratory furniture.

Additional Laboratory Workbench Surface Materials

In addition to the materials detailed above, laboratory workbench surfaces are available in other specialized materials, each tailored to distinct laboratory applications:

- High-Pressure Laminate (HPL): Durable and cost-effective, HPL surfaces are ideal for general-purpose laboratories, schools, and light industrial settings. They offer moderate chemical and moisture resistance and are available in a wide range of colors and finishes.

- PVC-Edged Laminate: Provides added edge protection and moisture resistance, suitable for educational labs and environments with frequent cleaning.

- Chemical-Resistant Laminate: Engineered for environments with occasional chemical exposure, offering a balance between affordability and performance.

- Composite Resin Wood: Combines the aesthetics of wood with improved chemical and impact resistance, recommended for technical workspaces and STEM classrooms.

Not sure which laboratory workbench material is right for your application? Review our laboratory surface selection guide or contact our experts for personalized recommendations based on your laboratory’s requirements.

Key Benefits of Modern Laboratory Workbenches

Investing in modern laboratory workbenches delivers significant benefits for scientific, educational, and industrial organizations. Here are some reasons why upgrading your lab workstations can enhance your laboratory’s performance and safety:

- Enhanced Safety: Modern bench materials and ergonomic designs reduce the risk of accidents, chemical spills, and repetitive strain injuries.

- Increased Productivity: Adjustable and customizable workbenches accommodate diverse workflows, improving efficiency and user comfort.

- Compliance and Certification: Selecting workbenches that meet industry standards (such as SEFA, NSF, ISO) supports regulatory compliance and audit readiness.

- Longevity and Value: Durable surfaces require less frequent replacement, reducing lifetime costs and environmental impact.

- Adaptability: Modular and mobile workbench designs allow laboratories to reconfigure spaces for new projects, equipment, or personnel changes.

- Cleanliness and Hygiene: Non-porous, antimicrobial, and easy-to-clean surfaces support laboratory cleanliness and reduce contamination risks.

Want to know how to maximize your lab’s return on investment with the right workbench? Explore strategies for selecting long-lasting, cost-effective laboratory furniture.

Buyer’s Guide: How to Select the Best Laboratory Workbench

Choosing the right laboratory workbench requires careful consideration of your unique laboratory processes, budgets, and regulatory requirements. Here’s a step-by-step approach to guide your purchase decision:

- Define Your Application: Identify the laboratory activities and equipment to be supported—chemical analysis, electronics assembly, biological research, sample preparation, and more.

- Assess Environmental Conditions: Consider temperature, humidity, chemical exposure, and the need for contamination control.

- Determine Required Certifications: Ensure compliance with relevant standards (such as SEFA, NSF, ESD, or FDA) based on your industry.

- Evaluate Ergonomics: Select adjustable or height-customizable benches to accommodate a range of users and tasks.

- Plan for Expansion: Choose modular or mobile bench systems that can adapt to future laboratory needs and equipment upgrades.

- Set a Budget: Balance upfront costs with long-term durability and maintenance requirements to maximize value.

- Request Samples or Demos: Ask suppliers for material samples, product demonstrations, or case studies relevant to your application.

Need help comparing laboratory workbench suppliers or manufacturers? Browse our Laboratory Workbench Supplier Directory or use our supplier comparison tool to shortlist reputable providers.

Choosing the Right Laboratory Workbench Supplier

To ensure you achieve the best results when purchasing laboratory workbenches, it’s essential to source your products from experienced and reputable suppliers. The right supplier can offer expert guidance, technical support, and product customization to match your specific laboratory needs.

When evaluating laboratory workbench suppliers:

- Compare at least five companies using our curated list of laboratory workbench manufacturers.

- Review each manufacturer’s business profile to understand their areas of expertise, capabilities, and product range.

- Utilize our built-in website previewer to explore each company’s offerings and customer testimonials.

- Request quotes and detailed product information directly using our convenient RFQ form—contact multiple businesses with a single submission.

- Assess warranty coverage, lead times, installation services, and after-sales support.

Want to streamline your procurement process? Use our simple RFQ system to reach multiple laboratory workbench suppliers and receive competitive quotes tailored to your project’s requirements.

For more information, explore our Laboratory Furniture Resources for planning tips, case studies, and frequently asked questions about lab workbenches.

Frequently Asked Questions about Laboratory Workbenches

- What is the best material for a laboratory workbench? The best material depends on your application—epoxy resin is ideal for chemical labs, stainless steel for sterile environments, phenolic resin for budget-conscious facilities, and maple wood for technical classrooms.

- How do I maintain and clean laboratory countertops? Use approved disinfectants and cleaning protocols appropriate for your bench material. Epoxy and phenolic resin surfaces are generally resistant to most cleaning agents.

- Can laboratory workbenches be customized for my space? Yes, most manufacturers offer bespoke sizes, configurations, integrated storage, electrical outlets, and modular accessories to fit your laboratory.

- What safety certifications should I look for in laboratory furniture? Look for SEFA, NSF, ESD, and ISO certifications to ensure compliance with industry standards.

- Which type of workbench is suitable for electronics assembly? ESD workbenches with static-dissipative surfaces and integrated grounding are essential for electronics labs.

Have more questions about laboratory workbenches or need a personalized recommendation? Contact our laboratory furniture specialists today for expert guidance and support.

55 Gallon Drums

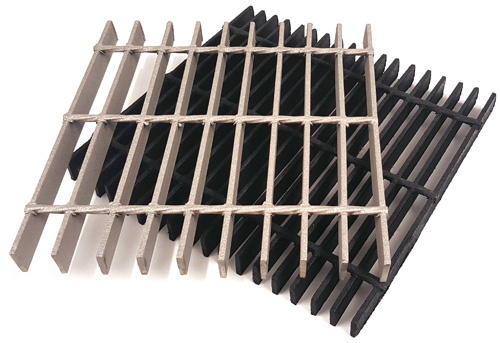

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

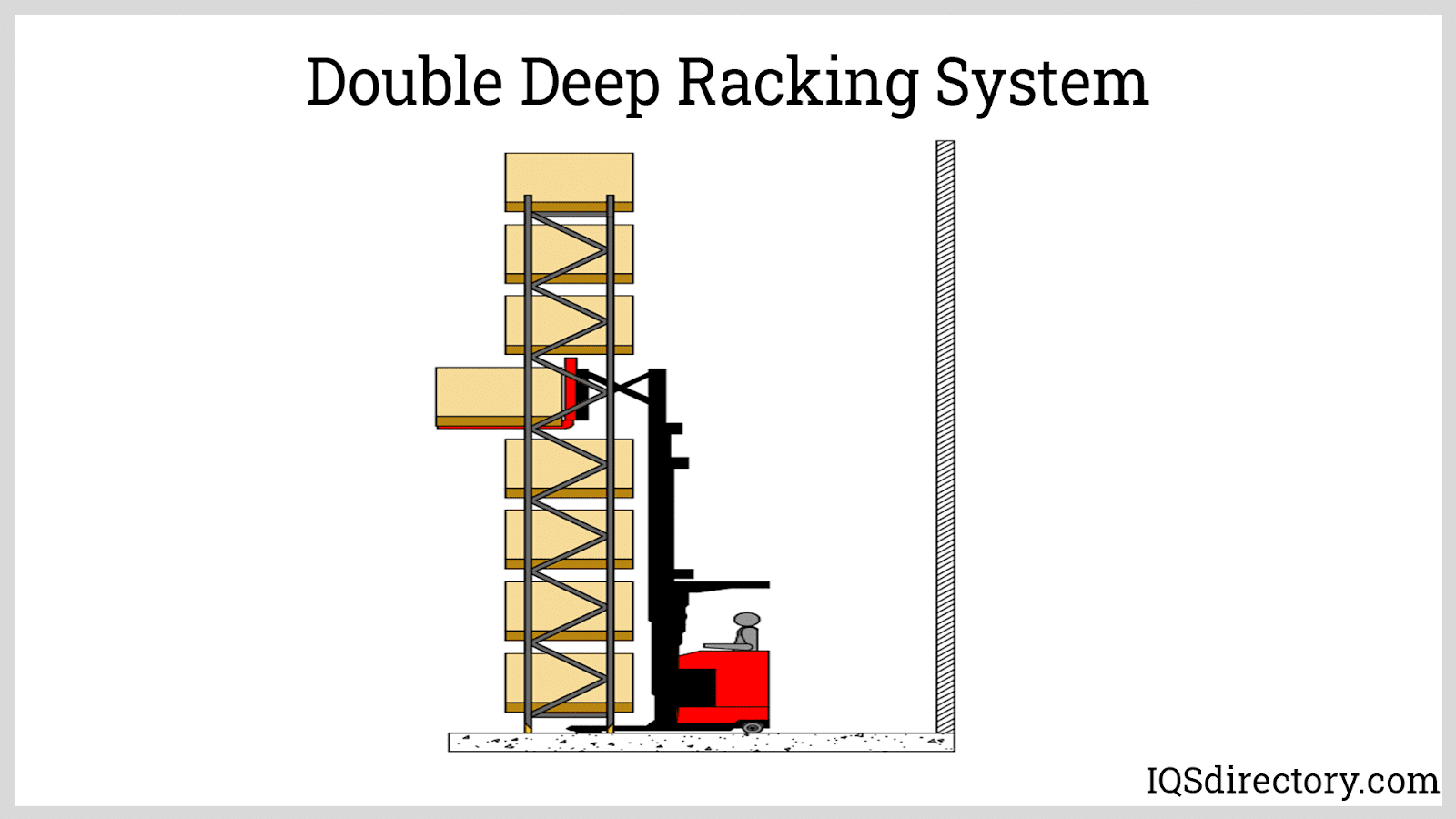

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services