ESD cleanroom benches are engineered workstations designed to meet two critical demands at once: controlling electrostatic discharge and preserving cleanroom integrity. In environments where sensitive components are exposed and contamination thresholds are extremely low, these benches provide a stable, controlled platform for precision work. Read More…

As a workstation manufacturer, Pro-Line offers industrial furnishing that increases employee productivity through creating an improved employee work environment.

Our workbenches come in a variety of styles including ergonomic height adjustable, chemical resistant, ball transfer surface, computer stations, laminar flow stations and more.

This progressive workstation manufacturer creates flexible, ergonomic solutions for a variety of work environments. ESD, clean room & lab benches, ball transfer assembly workstations, material handling flow rack stations, quick ship modular work benches & great accessories. With everything in-house, we ensure quality workmanship, great lead times & competitive prices for even custom bench designs.

Production Automation Corporation has been a distributor of products for general industrial manufacturing since 1973. We specialize in providing items used in electronic assembly and medical device manufacturing. As a manufacturer's representative, we have a large line of products such as anti fatigue mats, safety wear, chairs, cleaners, hand tools, microscopes, cabinets, workbenches and more.

Worksmart Systems designs ergonomic workstations providing customers with the necessary tools to reach six sigma lean manufacturing goals by eliminating waste, preventing defects and improving line efficiency. These are accomplished by our Fleximate® workstations such that our products can be joined together to create optimized assembly cells. We also offer floor and table top stations.

More ESD Cleanroom Bench Manufacturers

Their construction blends ESD-safe materials with cleanroom-approved finishes to support operations where static events, airborne particles, or workflow inefficiencies can result in costly failures.

These benches are commonly used in facilities operating within ISO Class 3 through ISO Class 8 cleanroom classifications. They incorporate grounded work surfaces, conductive or static-dissipative materials, and enclosed structural designs that align with both ESD standards and cleanroom regulations. The result is a workstation that protects delicate products while supporting consistent, repeatable processes.

Managing Static Risk in Controlled Environments

Electrostatic discharge poses a significant risk in industries such as electronics manufacturing, semiconductor production, aerospace assembly, and medical device fabrication. Static electricity can accumulate on personnel, tools, or surfaces and discharge suddenly into components that are highly sensitive to even minimal voltage. In cleanroom environments, where components are often miniaturized and densely packed, the consequences of ESD events are magnified.

ESD cleanroom benches are designed to manage this risk by safely channeling static energy away from the work area. Their work surfaces are manufactured within specific resistance ranges that allow static charges to dissipate gradually rather than discharging abruptly. This controlled dissipation protects components while maintaining a safe environment for operators and equipment.

Supporting Cleanroom Standards and Cleanability

Cleanroom compatibility extends beyond static control. Standard industrial benches can introduce contaminants through particle shedding, trapped debris, or chemical off-gassing. ESD cleanroom benches are specifically designed to minimize these risks through material selection and construction techniques.

Smooth, non-porous surfaces reduce particle generation and simplify cleaning routines. Sealed seams, flush fasteners, and rounded edges limit areas where contaminants can accumulate. Materials such as stainless steel, low-outgassing coated steel, and solid laminate or phenolic work surfaces are commonly used to withstand frequent cleaning with approved cleanroom solutions without degrading performance.

Industries and Applications

Electronics assembly and testing environments rely heavily on ESD cleanroom benches to protect printed circuit boards, microelectronics, and sensors throughout production and inspection stages. Semiconductor facilities use these benches for wafer handling, inspection, and packaging tasks that demand both static control and stringent cleanliness.

Medical device manufacturers depend on ESD cleanroom benches when producing implantable devices, diagnostic electronics, and other regulated products where contamination or static damage could lead to regulatory noncompliance or product recalls. Aerospace and defense operations also utilize these benches to safeguard high-value, mission-critical components while maintaining traceable, standardized workflows.

In laboratory and pharmaceutical cleanrooms, ESD cleanroom benches support analytical instruments, sample preparation, and controlled assembly processes where both static interference and contamination can compromise accuracy and results.

Construction Materials and Electrical Performance

Material selection plays a central role in the performance of an ESD cleanroom bench. Work surfaces are often constructed from static-dissipative laminates, conductive composites, or specialized ESD phenolic materials engineered to deliver uniform electrical properties across the entire surface. These materials are designed to resist wear and maintain consistent resistance values over extended service life.

Structural frames are typically fabricated from stainless steel or coated steel to resist corrosion, minimize particle shedding, and support grounding systems. Joints and hardware are designed to be flush and enclosed, reducing potential contamination points and supporting easy cleaning.

Grounding integration is a fundamental design consideration. ESD cleanroom benches are built to connect seamlessly with facility grounding infrastructure and often include dedicated grounding points for wrist straps, mats, and tools. This ensures a continuous and reliable path for static dissipation throughout the workstation.

Ergonomic Design and Workflow Efficiency

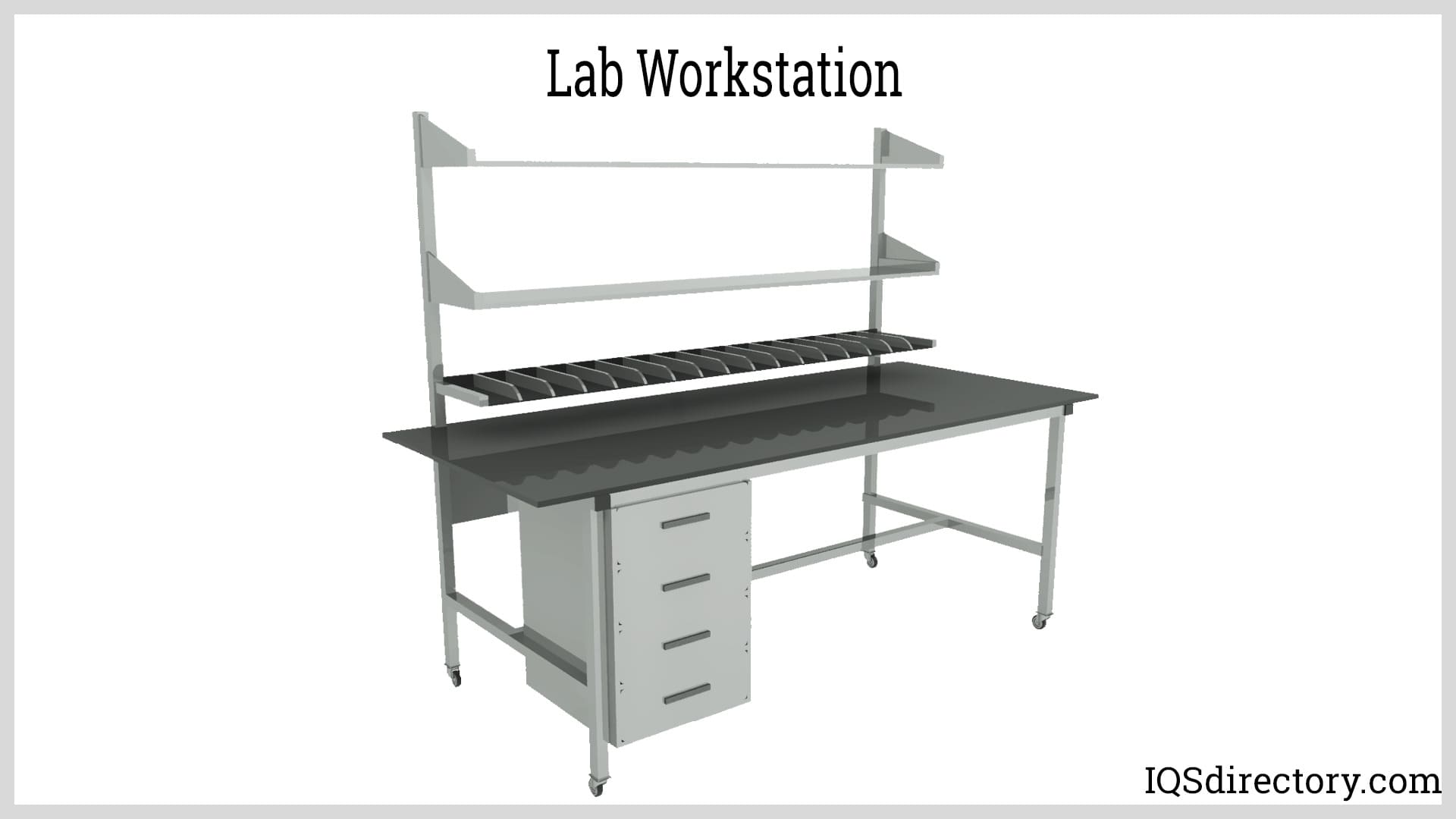

Effective ESD cleanroom benches balance technical performance with operator usability. Many designs incorporate adjustable height mechanisms, allowing operators to alternate between seated and standing positions. Proper ergonomics reduce physical strain, improve precision, and help maintain productivity during extended work periods.

Cleanroom-rated accessories such as task lighting, shelving, monitor mounts, and integrated power options are frequently available to enhance organization without disrupting airflow or cleanliness. Thoughtful layouts help keep tools and components accessible while minimizing unnecessary movement that could disturb cleanroom conditions.

Modular Systems and Customization Options

Cleanroom processes vary widely, making adaptability an important consideration. Modular ESD cleanroom bench systems allow facilities to tailor workstations to specific applications by adding drawers, instrument shelves, enclosures, or lighting components without compromising ESD or cleanroom compliance.

Customization may include nonstandard dimensions, increased load capacities, or integration with laminar flow units and enclosures. These options enable organizations to align workstations with their exact operational requirements while maintaining compliance with electrostatic discharge and cleanroom standards.

What Buyers Evaluate When Selecting Benches

Buyers assessing ESD cleanroom benches focus on several core criteria. Compatibility with the required cleanroom classification is essential, as materials and construction must support the targeted ISO level. Electrical performance of the work surface must meet recognized ESD standards to ensure consistent static control.

Durability is another key factor, particularly in high-throughput or regulated environments. Buyers often seek benches that maintain stable ESD properties despite frequent cleaning, heavy use, and exposure to approved solvents. Structural integrity, corrosion resistance, and ease of maintenance all contribute to long-term value.

Flexibility and scalability also influence purchasing decisions. Modular systems that can be reconfigured or expanded over time allow facilities to adapt to new processes or increased production without replacing entire workstations.

Long-Term Value of Quality ESD Cleanroom Benches

High-quality ESD cleanroom benches play a direct role in protecting product quality and improving operational efficiency. By reducing the likelihood of electrostatic damage, they help minimize scrap, rework, and costly failures. Their cleanroom-compatible construction supports compliance with regulatory and quality standards across highly controlled industries.

Well-designed benches also improve organization and operator comfort, contributing to smoother workflows and fewer errors. Over time, these advantages translate into improved consistency, higher yields, and more reliable manufacturing outcomes.

Meeting Broad Buyer and Research Needs

From engineers evaluating static control strategies to procurement teams comparing cleanroom workstation specifications, ESD cleanroom benches address a wide spectrum of buyer intent. They represent the intersection of contamination control, ESD protection, ergonomic design, and modular flexibility, making them a foundational component of modern cleanroom operations.

By understanding how application demands, material choices, and design features work together, organizations can select ESD cleanroom benches that meet today’s requirements while remaining adaptable for future growth. In precision-driven environments where failure is not an option, these benches are essential to protecting both products and processes.

55 Gallon Drums

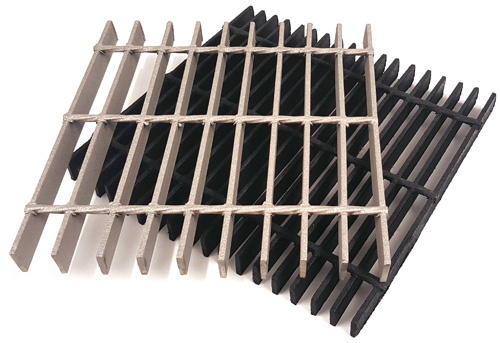

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

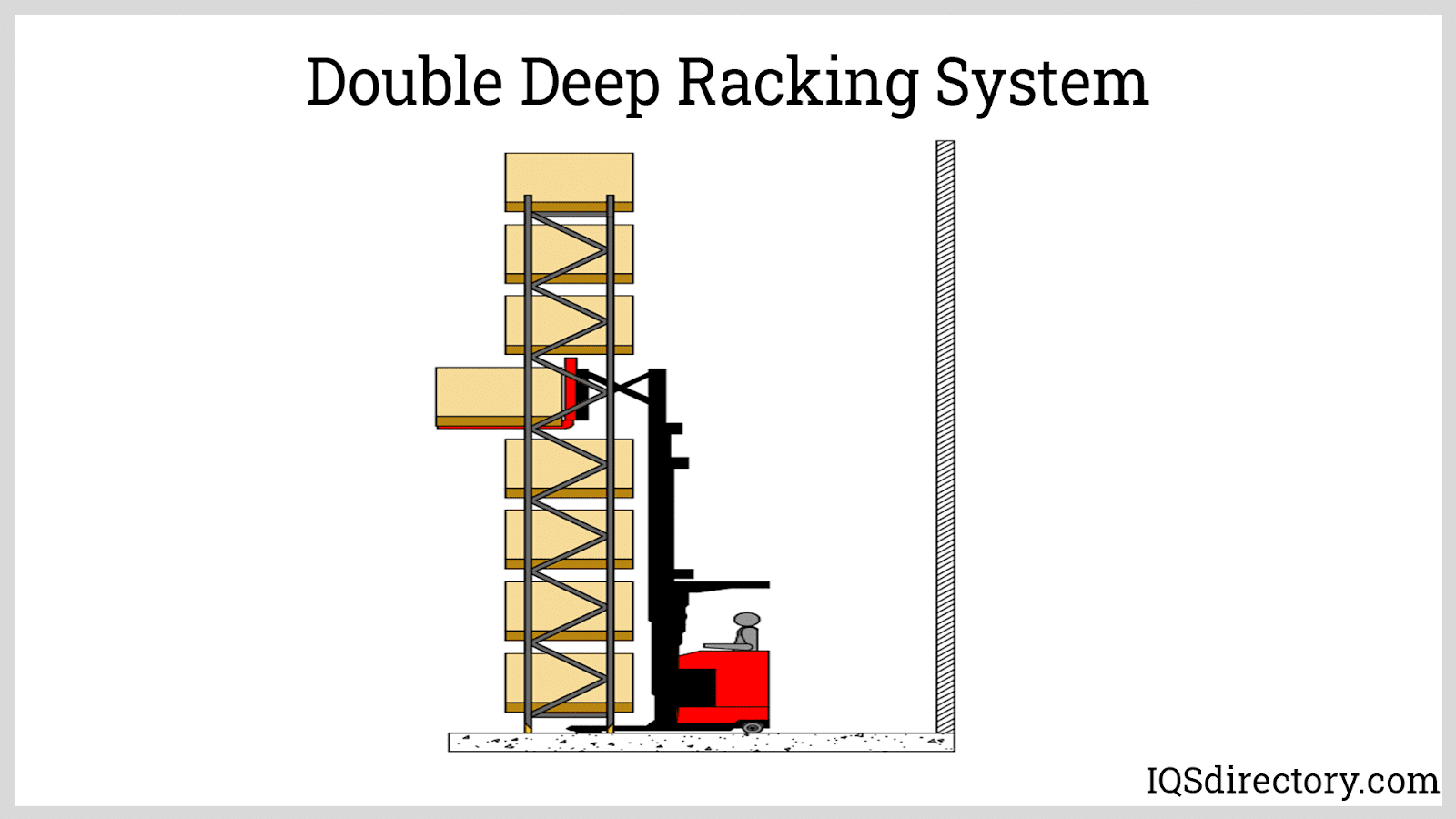

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services