Manufacturers usually build metal workbenches using stainless steel because of its anti-corrosive qualities. Stainless steel creates a rigid frame and gives the workbench a finished look. Stainless steel is also very easy to clean if the bench is being used in a setting where cleanliness is important. Read More…

Our workbenches come in a variety of styles including ergonomic height adjustable, chemical resistant, ball transfer surface, computer stations, laminar flow stations and more.

As a workstation manufacturer, Pro-Line offers industrial furnishing that increases employee productivity through creating an improved employee work environment.

This progressive workstation manufacturer creates flexible, ergonomic solutions for a variety of work environments. ESD, clean room & lab benches, ball transfer assembly workstations, material handling flow rack stations, quick ship modular work benches & great accessories. With everything in-house, we ensure quality workmanship, great lead times & competitive prices for even custom bench designs.

Production Automation Corporation has been a distributor of products for general industrial manufacturing since 1973. We specialize in providing items used in electronic assembly and medical device manufacturing. As a manufacturer's representative, we have a large line of products such as anti fatigue mats, safety wear, chairs, cleaners, hand tools, microscopes, cabinets, workbenches and more.

Worksmart Systems designs ergonomic workstations providing customers with the necessary tools to reach six sigma lean manufacturing goals by eliminating waste, preventing defects and improving line efficiency. These are accomplished by our Fleximate® workstations such that our products can be joined together to create optimized assembly cells. We also offer floor and table top stations.

More Steel Workbench Manufacturers

Steel Workbench: Essential Guide to Types, Uses, and Buying Considerations

A steel workbench is a staple of modern workshops, industrial facilities, laboratories, and manufacturing environments. These highly durable workstations are designed to withstand heavy-duty use and offer unparalleled stability, strength, and versatility. Whether you are outfitting a commercial production floor, setting up a home garage, or upgrading your laboratory furniture, steel workbenches are a top choice for professionals and hobbyists alike.

What Is a Steel Workbench?

A steel workbench is a robust table constructed primarily from steel, offering a sturdy, long-lasting platform for a wide range of tasks. Unlike wooden workbenches, steel models are resistant to warping, corrosion, and impact damage, making them ideal for environments that demand reliability and easy maintenance. Steel workbenches are available in various sizes, load capacities, and configurations to suit specific applications, including assembly, repair, fabrication, and electronics work.

Common Applications and Use Cases for Steel Workbenches

Steel workbenches can be used for many purposes, and their adaptability has made them a mainstay across industries. Some of the most common applications for steel workbenches include:

- Industrial Manufacturing: Heavy-duty steel workbenches support assembly lines, fabrication processes, and quality control stations in factories.

- Automotive Workshops: Mechanics rely on steel workbenches for engine rebuilds, parts cleaning, and tool organization.

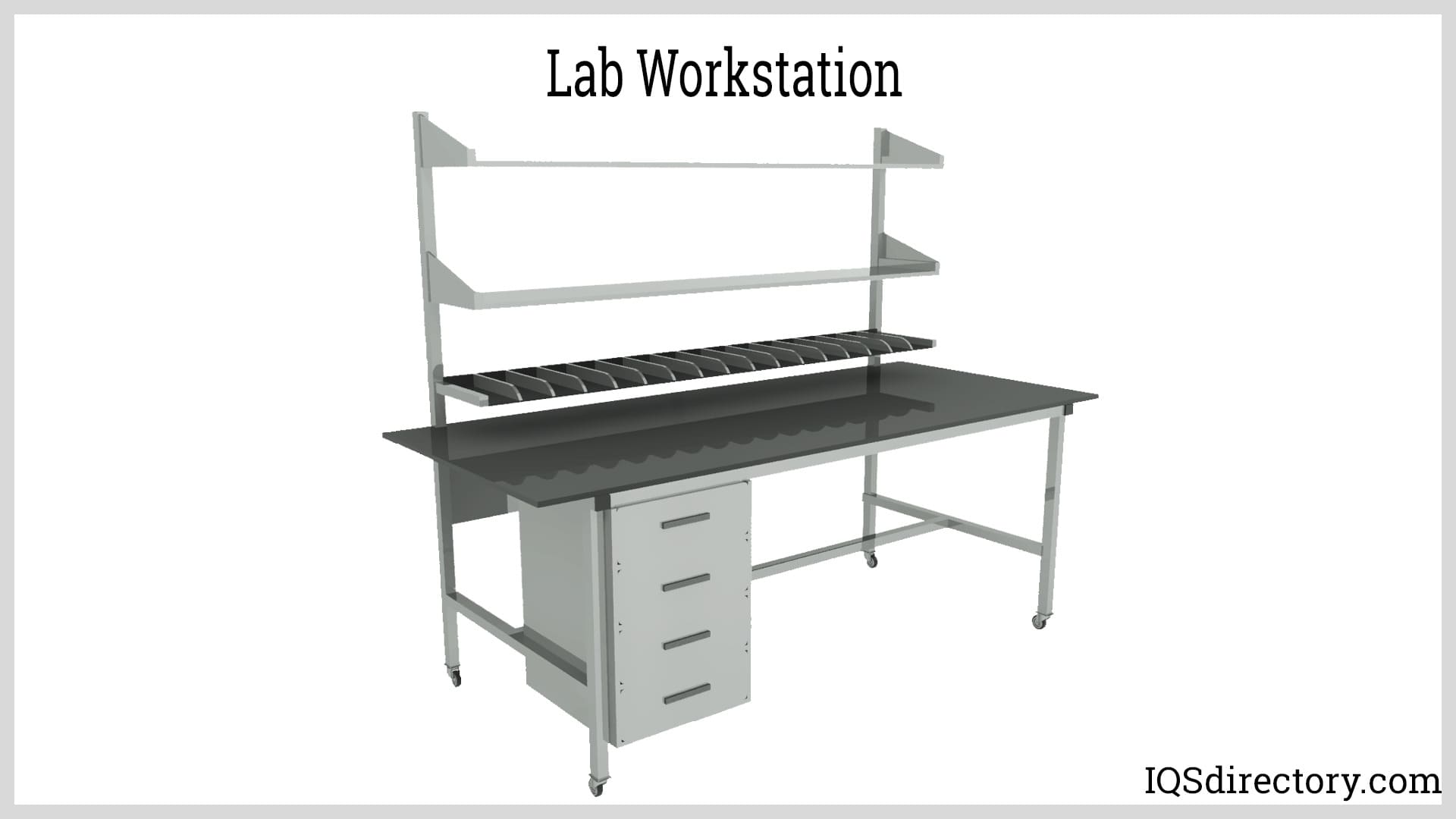

- Laboratories: Chemical-resistant steel benches are standard in labs handling volatile substances or requiring sterile conditions.

- Electronics Assembly: ESD-safe steel workbenches are used for circuit board assembly and repairs.

- Home Garages and DIY Spaces: Homeowners and hobbyists benefit from the durability and utility of steel workbenches for woodworking, metalworking, and various projects.

- Packing and Shipping Departments: Steel benches with integrated shelving and bins streamline order fulfillment and inventory management.

- Cleanrooms and Medical Facilities: Stainless steel workbenches are essential where hygiene and contamination control are critical.

Wondering which steel workbench is right for your industry? Explore our guide below or contact a specialist to discuss your specific application requirements.

Types of Steel Workbenches

Given their versatility, steel workbenches come in a variety of designs and configurations. Understanding the different types can help you select the best solution for your needs:

- Standard Steel Workbench: A basic, flat work surface with a sturdy steel frame. Ideal for general use in a wide range of environments.

- Adjustable Height Workbench: Allows users to set the optimal working height for ergonomic comfort, which is especially important for tasks requiring precision or for accommodating different users.

- Mobile Steel Workbench: Equipped with caster wheels for easy mobility. These rolling workbenches are perfect for dynamic workspaces where flexibility is needed.

- Folding Steel Workbench: Features collapsible legs or surfaces for compact storage when not in use—a great choice for small workshops or multi-purpose spaces.

- Heavy Duty Workbench: Engineered to support significant weight loads, often used in manufacturing and automotive environments where durability is paramount.

- Stainless Steel Workbench: Provides superior corrosion resistance, making it suitable for food processing, laboratories, and cleanrooms.

- Workbench with Storage: Includes built-in drawers, shelving, or cabinets for tool storage and organization.

- ESD-Safe Workbench: Designed to safely dissipate electrostatic discharge for electronics assembly and repair.

Do you need a mobile steel workbench or a heavy-duty steel workbench? Contact our team for personalized recommendations based on your workflow and operational needs.

Key Features and Customization Options

Today's steel workbenches are engineered for both performance and adaptability. When evaluating workbench options, consider these popular features and add-ons that can enhance productivity and safety:

- Integrated Storage Solutions: Drawer units, cabinets, and overhead shelving improve organization and accessibility for tools and materials.

- Lockable Compartments: Secure valuables, sensitive tools, or hazardous substances in lockable drawers or cabinets.

- Built-In Power Outlets: Electrical outlets and USB ports are integrated into the frame for easy access to power tools and electronic devices.

- Overhead Lighting: LED or fluorescent lighting can be incorporated to improve visibility, especially for detailed tasks.

- Adjustable Feet or Casters: Leveling feet ensure stability on uneven floors, while casters provide mobility for reconfiguring workspaces.

- Modular Accessories: Pegboards, tool racks, vice mounts, and bin rails can be added to customize the workbench for specific jobs or processes.

- Work Surface Options: Choose from solid steel, stainless steel, or laminated tops to match your application’s durability and cleanliness requirements.

- ESD-Safe Surfaces: Essential for electronics assembly or repair to prevent static damage to components.

Curious about which workbench accessories will best support your workflow? Find out more here.

Manufacturing Process of Steel Workbenches

The production of steel workbenches begins in a metal fabrication plant, where raw steel sheets are meticulously transformed into functional, high-quality workstations. Here’s a step-by-step overview:

- Material Selection: High-grade steel, often with anti-corrosion coatings or stainless steel, is chosen for durability and longevity.

- Cutting and Shaping: Steel sheets are cut down to precise sizes and shaped into legs, frames, and work surfaces. This can involve heating the steel for molding or using cold-press techniques for bending.

- Welding and Assembly: The shaped components are welded together, either by skilled technicians or automated welding machines. Automated systems ensure consistent, high-strength welds that are essential for bearing heavy loads.

- Surface Finishing: The bench is sanded, polished, and treated with powder coating, paint, or other finishes to resist corrosion and enhance appearance.

- Quality Control: Each unit undergoes rigorous testing for stability, strength, and workmanship before leaving the factory.

- Accessory Installation: Drawers, shelves, electrical outlets, and other features are installed according to customer specifications.

This thorough manufacturing process ensures that steel workbenches deliver outstanding performance, safety, and longevity in demanding industrial and commercial environments.

Advantages of Choosing a Steel Workbench

Why should you invest in a steel workbench over alternatives like wood or plastic? Here are the key benefits that set steel workbenches apart:

- Exceptional Strength and Load Capacity: Steel workbenches can support heavy equipment, machinery, and materials without flexing or sagging.

- Longevity and Durability: Resistant to impacts, chemicals, and corrosion, steel benches maintain their integrity for years—often decades—in rigorous settings.

- Easy to Clean and Maintain: Non-porous steel surfaces wipe clean effortlessly, making them ideal for sterile or messy environments.

- Fire and Heat Resistance: Steel is naturally fire-resistant, providing a safer workspace in high-risk areas.

- Customizable for Any Task: With a range of modular accessories and configurations, steel workbenches can be tailored to unique workflows.

- Professional Appearance: Sleek, modern steel benches project a professional image in labs, workshops, and industrial spaces.

- Environmentally Friendly: Steel is recyclable, and many manufacturers use recycled steel in their benches for a reduced environmental footprint.

Considering the benefits of steel workbenches for your business or home workshop? Request a consultation to see how steel can transform your workspace efficiency.

Factors to Consider When Buying a Steel Workbench

Choosing the right steel workbench involves evaluating several decision factors to ensure you get the best value and performance for your investment. Here’s what to keep in mind:

- Intended Use: Define your primary tasks—heavy-duty fabrication, electronics assembly, laboratory work, etc.—to guide your requirements.

- Weight Capacity: Match the bench’s load rating to your heaviest equipment or materials to prevent structural failure.

- Dimensions: Consider the available space and select a bench size that fits your workshop or facility layout.

- Work Surface Material: Choose stainless steel for corrosion resistance, powder-coated steel for general use, or laminated tops for specialized applications.

- Mobility Needs: Decide if you need stationary or mobile (rolling) workbenches, especially if your workspace layout changes frequently.

- Storage Requirements: Determine the amount and type of storage—drawers, shelves, cabinets—you need for tools and supplies.

- Ergonomics: Select adjustable height models to accommodate multiple users and reduce fatigue.

- Compliance: Ensure your workbench meets industry standards for safety, hygiene, or static control (ESD) where applicable.

- Budget: Balance initial cost with long-term durability and reduced maintenance to maximize ROI.

Still unsure which steel workbench is right for you? Ask yourself:

- What are the main tasks I’ll perform on the workbench?

- How much weight will it need to support?

- Do I need mobility or will it remain stationary?

- How important is integrated storage or power access?

- What are my space constraints?

Get expert advice tailored to your needs—schedule a free consultation with our workbench specialists today.

Steel Workbench Maintenance and Care

Proper maintenance extends the life and performance of your steel workbench. Here are best practices to ensure your bench remains in top condition:

- Regular Cleaning: Wipe down surfaces with a mild detergent to remove grease, dust, and debris.

- Inspect for Damage: Periodically check for dents, rust, or loose welds, especially in high-stress areas.

- Lubricate Moving Parts: Apply lubricant to casters, drawer slides, and hinges to maintain smooth operation.

- Protect Against Corrosion: For painted or powder-coated benches, touch up chips promptly to prevent rust.

- Follow Manufacturer Guidelines: Adhere to the recommended load limits and accessory installation instructions.

Want more tips on keeping your industrial workbenches in peak condition? Read our maintenance guide.

Steel Workbench Accessories and Upgrades

Enhancing your steel workbench with the right accessories can significantly improve productivity, safety, and organization. Popular add-ons include:

- Tool Storage Drawers: Keep frequently used tools organized and within reach.

- Power Strips and Charging Stations: Add convenience for powering tools and charging devices.

- Pegboards and Tool Racks: Hang hand tools, clamps, and accessories for easy access and visibility.

- Lighting Kits: Task lighting ensures you can see fine details and reduces eye strain.

- Anti-Fatigue Mats: Place these underfoot to enhance comfort during long hours of standing.

- Vice Mounts and Clamps: Secure workpieces for sawing, sanding, or assembly tasks.

- Bins and Parts Organizers: Sort and store small parts, fasteners, and hardware efficiently.

Looking for the best steel workbench accessories for your application? Explore our top recommendations to customize your bench for maximum utility.

Frequently Asked Questions About Steel Workbenches

- What is the typical weight capacity of a steel workbench? Most standard steel workbenches support loads from 500 lbs to over 5,000 lbs, depending on design and construction.

- Are steel workbenches suitable for outdoor use? Powder-coated or stainless steel workbenches offer weather resistance, but it’s best to verify specifications for outdoor environments.

- Can I retrofit accessories to existing workbenches? Many modular accessories are compatible with standard workbench frames—check with your manufacturer for specific fitment.

- Do steel workbenches require assembly? Most benches ship flat-packed and require on-site assembly; detailed instructions and all necessary hardware are usually included.

- How do I choose between stainless steel and powder-coated steel? Stainless steel is ideal for chemical resistance and hygiene, while powder-coated steel offers excellent durability for general industrial use at a lower cost.

Have more questions? Browse our complete steel workbench FAQ or contact our support team.

Where to Buy Steel Workbenches

Ready to purchase a steel workbench for your workshop, factory, or laboratory? Leading manufacturers and distributors offer a wide range of steel workbenches, from standard models to fully customized solutions. Consider these shopping tips:

- Choose reputable suppliers with a track record of quality and customer service.

- Look for brands that offer warranties and after-sales support.

- Ask about bulk pricing, delivery, and installation services for large orders.

- Read customer reviews and testimonials to gauge product satisfaction.

- Request product catalogs or technical datasheets to compare specifications.

Ready to find the best steel workbench for your needs? Browse our product selection or request a quote tailored to your requirements.

Conclusion: Invest in Quality with a Steel Workbench

Steel workbenches are the gold standard for strength, durability, and versatility in work environments ranging from heavy industry to precision laboratories. With a vast array of models, customization options, and accessories, there’s a steel workbench to fit every workspace and workflow. By carefully considering your specific needs, budget, and intended use, you can select a workbench that will serve you reliably for years to come.

For expert guidance on selecting, configuring, and maintaining your steel workbench, connect with our experts today and unlock the full potential of your workspace.

55 Gallon Drums

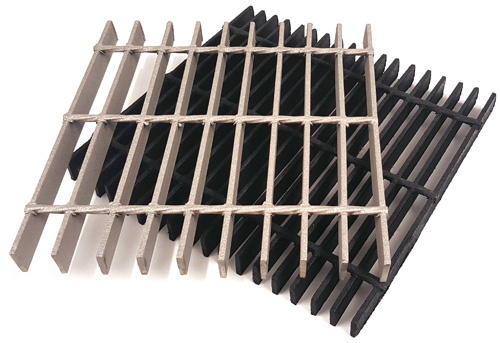

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services